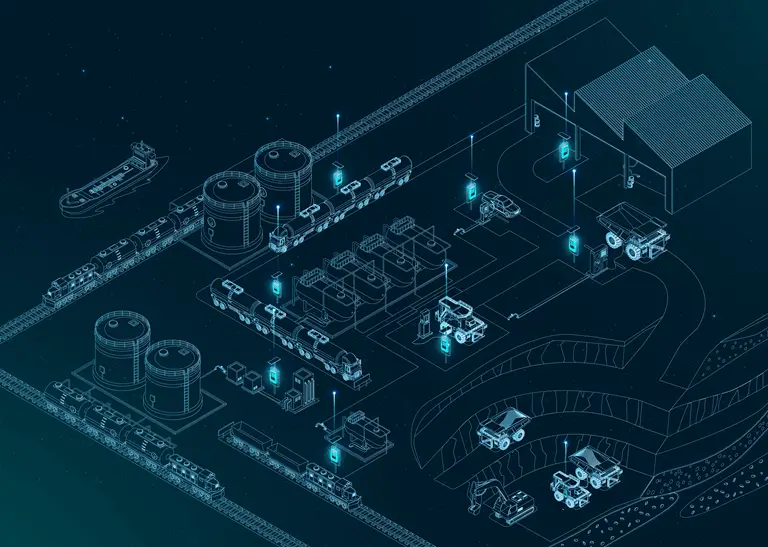

With roots in Sydney and operations spanning more than 300 sites across nine countries, VERIDAPT has evolved from a fuel-tracking innovator into a global platform for environmental, social and governance (ESG) data, emissions transparency, and real-time fleet optimisation.

According to VERIDAPT chief executive officer David Thambiratnam, demand for actionable fuel data has surged in recent years, as mining companies work to meet ambitious decarbonisation targets.

“For a long time, fuel tracking was about managing costs, asset efficiency, and handling tax rebates,” Thambiratnam told Australian Mining. “But with increasing focus on emissions reduction targets, our customers are now using that same data to drive meaningful action.”

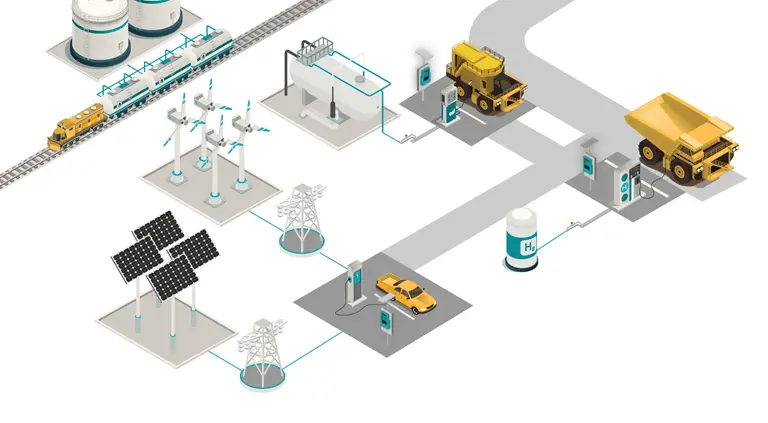

Fleet operations can account for 65-90 per cent of a mine's energy use, and with electrification of heavy vehicles still in its infancy, operators are leaning heavily on data-driven fuel management tools to cut emissions.

This means understanding every litre consumed, every vehicle filled, and every variance in efficiency.

“In the past, you might have reported your fuel use and left it there,” Thambiratnam said. “Now the question is, ‘How do I reduce it?’. And the only way to do that is with more granular, real-time data to provide the knowledge to effect real change.”

VERIDAPT's singleplatform fuel managementsolution integrates directly with fleet infrastructure and procurement systems to capture detailed insights about fuel types, vehicle usage, and energy costs.

From diesel to biodiesel, renewable diesel to electricity, the platform gives miners a single source of truth across multiple fuel streams, which is crucial in an era of blended energy strategies.

“Our customers are going to be in this mixed-mode of energy for at least the next 10 years,” Thambiratnam said. “You can’t reliably manage that through three or four different platforms – you need one system that can handle it all.”

VERIDAPT’s hardware is rugged and internet-enabled, allowing fast installation and minimal intervention. The company can remotely monitor and update systems to ensure uptime and data integrity.

“Once the hardware’s installed, we manage it remotely,” Thambiratnam said. “We can tell if something doesn’t make sense, flag anomalies and guide customers to fix them so the data is always accurate and actionable.”

This robust design underpins major operational savings. One key benefit for many customers, particularly Tier 1 miners, is the ability to significantly reduce misappropriation and fuel theft.

“Even in Australia, we’ve seen fuel consumption drop 10 to 15 per cent overnight after access controls are introduced,” Thambiratnam said.

“By having a swipe card to access fuel, making it traceable to a person and a vehicle, the system closes loopholes fast.”

VERIDAPT also helps unlock tax efficiency gains, with Australian miners relying on fuel tax rebates worth tens or even hundreds of millions each year. These tax benefits depend on accurate tracking and proof that fuel was used off-road.

“Our data helps customers secure their rebates with confidence,” he said. “In some cases, the return on investment just from the rebate benefit far outweighs the cost of the system.”

Procurement is another area ripe for optimisation. By digitising the fuel delivery process and automating the reconciliation between delivery documentation and actual tank readings, VERIDAPT enables shorter payment cycles and smoother supplier relationships.

“Some of our more advanced customers have negotiated better rates by paying within 10 days instead of 60,” Thambiratnam said. “This is only possible because our system gives them instant verification of fuel deliveries against the bills of lading.”

Operationally, VERIDAPT supports predictive maintenance and fleet optimisation by pinpointing anomalies in fuel consumption.

If a vehicle suddenly starts using more fuel, the data can flag it for review before costs spiral or emissions increase.

“All of this begins with solving one simple problem: knowing exactly where your fuel goes,” Thambiratnam said. “Once you’ve done that, you can answer all kinds of strategic questions about energy cost and savings, fleet performance, and sustainability.”

VERIDAPT’s platform remains lean by design. Its tech stack is streamlined for remote deployment, allowing local contractors or customers themselves to install the systems.

Ongoing support sees the company help customers integrate the platform into business processes like procurement, reporting, and maintenance.

This service has seen VERIDAPT establish an enviable track record.

“We’ve never lost a customer in 20 years,” he said. “In Australia, I’d estimate around 70 per cent of mining fuel is going through our systems, and in industrial rail it’s closer to 90 to 95 per cent.”

With an industry still years away from full electrification and an ESG imperative driving every major operational decision, VERIDAPT’s platform is shaping how miners manage energy today and preparing them for the green transition ahead.

“It’s not just about emissions reporting,” Thambiratnam said. “It’s about optimisation, accountability and being ready for whatever comes next.”