Fuel and lubricants are often some of the most significant costs at any mine, sometimes making up over 20% of total operational expenses. Whether your site is in the Americas, Africa, or anywhere else globally, how you buy, store, manage, and use fuel makes a huge difference to your profits. The profit impact can be larger in the demanding operational environments often found in Latin America and Africa. Effective fuel and lubricant management can help you significantly cut operating costs, with industry reports showing potential fuel savings often ranging from 3% to 10% or even more. This translates not only to financial gains but also to getting more done and lowering risk.

VERIDAPT works with some of the world's biggest and most efficient mining companies, many with significant operations in Latin America and Africa. Based on this global experience, we have created this guide to share the best ways to manage fuel and fuel operations using Fuel Management Systems. For instance, some FMS systems have helped the African mining industry save over a million dollars a month by improving fuel efficiency and reducing theft, downtime and waste.

Getting started with smart fuel management (applicable worldwide):

It's helpful to:

-

Learn the basics of how to manage fuel and lubricants effectively.

-

See the benefits of a sound fuel management system (FMS) for your region, including achieving fuel reconciliation rates above 99.5%, drastically reducing losses from theft or errors that can otherwise account for 2-6% of total fuel spend.

-

Work with your FMS vendor to learn how to set up and manage a fuel management system specific to your mine site's needs.

You won’t achieve perfect fuel management overnight. It takes commitment from your team, time, and smart choices. Don't feel stressed about setting this up. Working with your FMS vendor, establish a baseline understanding of your current fuel usage and losses. Learn the areas in your current system that have the most significant potential to increase efficiency and savings. Then, make a plan to improve things step by step. By following this guide, you’ll see real savings. Many companies find that a well-implemented fuel management system can pay for itself in months, leading to improved profits in mines like those in Australia, Latin America, and Africa. This guide focuses on improving fuel management from fuel ordering to consumption and fuel reconciliation.

(FAQs) - global solutions, local impact

Here are answers to some common questions about how VERIDAPT helps mining and rail companies in Latin America, Africa, Canada, and around the world manage fuel and lubricants better:

1. What is VERIDAPT's AdaptFMS platform?

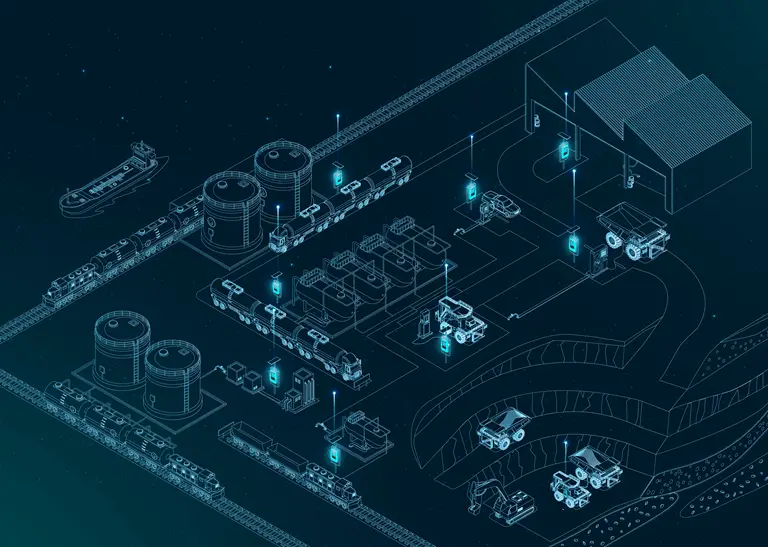

AdaptFMS is VERIDAPT's system for managing fuel and emissions. It's used in mining and rail operations globally, including sites in Latin America and Africa, and tracks over 30 billion liters of fuel around the world each year.

2. How can fuel management lower costs for mining operations in regions like Latin America or Africa?

By carefully tracking fuel use, cutting down on waste (which can be a significant hidden cost), and using fuel smartly with the help of data, mining companies can greatly reduce their fuel-related costs. A 1% improvement in fuel efficiency can translate into saving over a million liters of diesel a year for a large mine, a crucial factor for lowering costs and improving efficiency.

3. Does VERIDAPT also help the rail industry in emerging markets?

Yes, VERIDAPT provides digital fuel management to major rail companies globally, helping them use fuel more efficiently and track emissions as they happen. This is vital for infrastructure development and operational efficiency in many parts of Latin America and Africa.

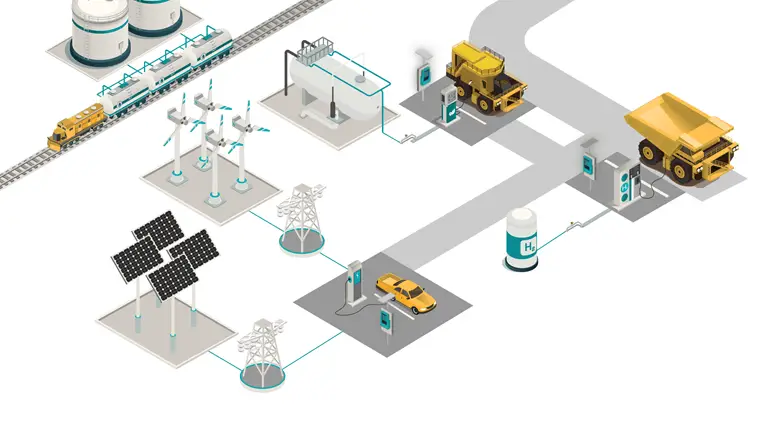

4. Can VERIDAPT's system help with ESG (Environmental, Social, and Governance) goals, especially in developing regions?

Definitely, VERIDAPT’s digital tools help companies track their energy use and emissions. Reducing fuel consumption directly cuts down on CO2 emissions – for example, saving 1.3 million liters of diesel can equate to reducing CO2 emissions by around 3,500 tonnes. This is key for meeting ESG targets, which are increasingly important for miners and rail operators in Latin America, Africa, and worldwide.

5. What kinds of companies use VERIDAPT's fuel management (FMS) technology?

Veridapt's clients include leading global mining and rail companies such as BHP, Rio Tinto, Glencore, Vale, Teck, and Syncrude.

Who is VERIDAPT?

VERIDAPT is a leading global innovator in fuel and emissions management technology (FMS), monitoring over 30 billion liters of fuel annually for major mining and rail operations worldwide. Veridapt’s AdaptFMS platform is used by the world's largest global mining and rail companies. at more than 80 large global sites.

For over 20 years, VERIDAPT has been the innovation leader in digital energy management. We operate in Australia, North and South America (covering Latin America), Africa, and the Asia-Pacific region. We offer a fully digital way to track and improve efficiency in fuel usage and lower emissions. This is especially important now as mining and rail businesses worldwide, including those in Latin America and Africa, look for better ways to improve efficiency, achieve significant cost reductions (often in the millions of dollars annually for large operations), and meet ESG goals.

This article is an excerpt from Veridapt’s Fueling Best Practice Guide for Mines. For more information, download the complete guide here.