VERIDAPT is a recognised expert in fuel management, delivering solutions that can significantly enhance fuel control.

As mining companies face increasing cost and equipment uptime pressures, optimising fuel-management processes can not only save money but set operators up for future prosperity.

The mining sector is harnessing digitalisation and Internet of Things (IoT) solutions to access enhanced fuel-management practices, thanks in large part to innovative IoT company VERIDAPT.

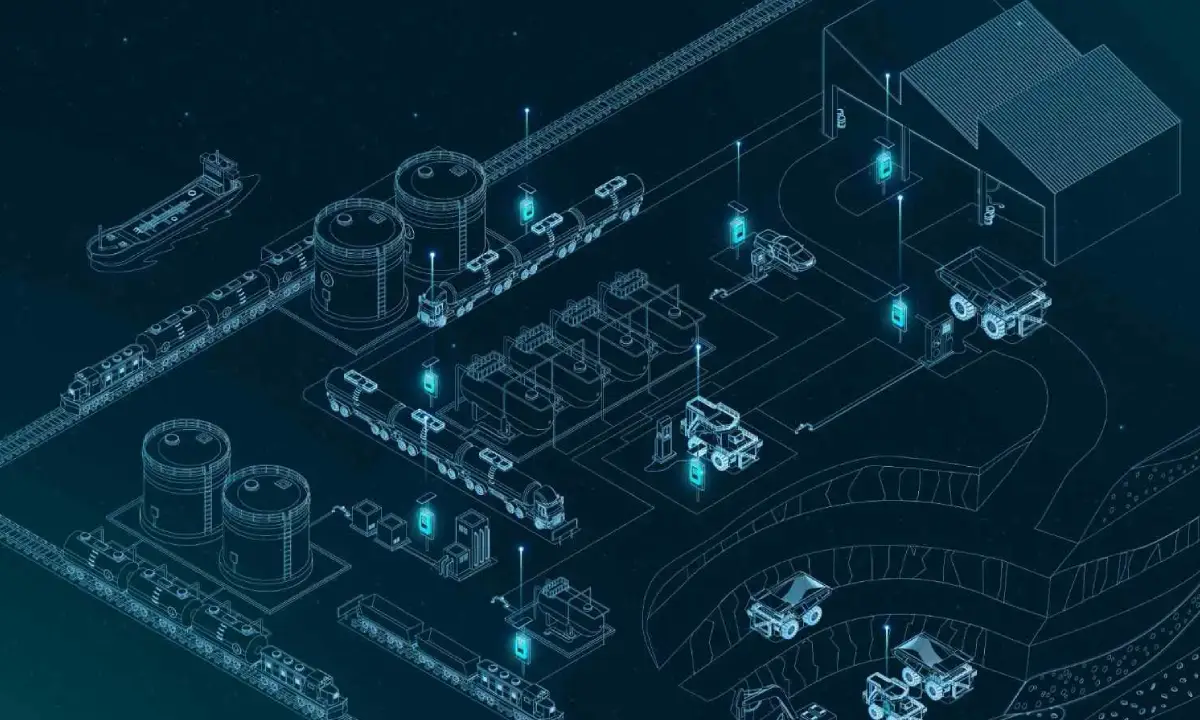

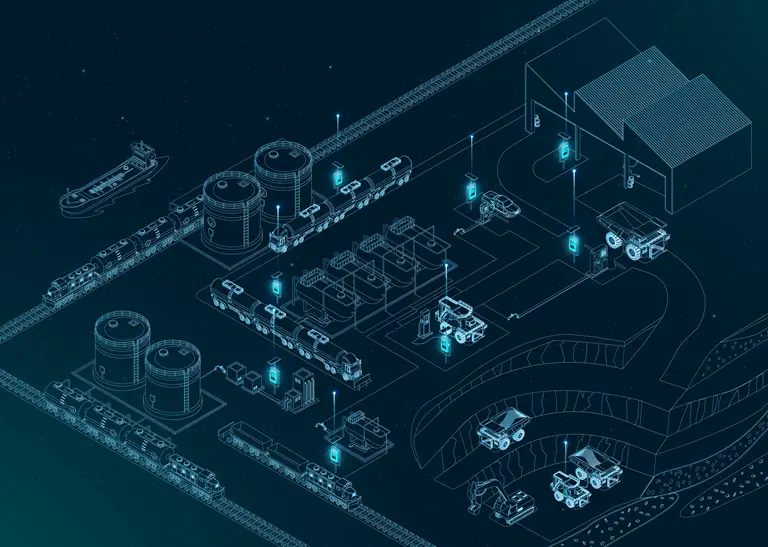

For VERIDAPT, refining fuel management for its utmost effectiveness involves providing data capture and analysis capabilities coupled with the expertise to develop a digital twin model to help operators visualise and optimise their fuel supply chain.

VERIDAPT’s platform has been adopted by multiple Tier 1 mining companies, with one miner receiving a detailed analysis on replacing its existing direct-to-tank processes with a tailored hub-and-spoke model.

The comprehensive and predictive modelling clearly demonstrated the operator would lower both capital expenditure (capex) and operational expenditure (opex) on fuel delivery and distribution by between $US5 million–6 million.

VERIDAPT vice president mining Wayne Arthur explained how this project came about.

“By leveraging our in-house data-science capability, we were conducting analytics on a mining client’s data,”

Arthur told Australian Mining. “We determined that we could build a digital twin model to run scenarios and see if improvements could be made to their fuel supply chain.”

Arthur said VERIDAPT worked with the mining company to understand their current fuel storage capacity and the criticality of certain fuel-storage locations.

The digital twin model, based on VERIDAPT’s fuel-management platform, enabled the analytics team to run potential scenarios and scope what adaptations would work best.

“There’s a lot of logistics and protocols that can make fuel delivery on a mine site complex,” Arthur said.

“Through the hub-and-spoke model, the client was able to have fuel supplied to a central on-site hub rather than to individual tanks, which have much smaller storage capacities.”

Combine the smaller storage with the added logistics of delivering fuel to each tank and operators face greater supply-chain risk with a direct-to-tank model.

By contrast, a hub-and-spoke model provides the operator with greater ‘survival time’.

“Having a central hub means that if there’s any disruptions to a fuel supply chain, you have continuity for a significant amount of time, which is what we call survival time,” Arthur said.

“Let’s say, for example, that storage on-site is one million litres, and the operator uses 250,000 litres per day, this means they have four days of survival time.

“A hub-and-spoke model enables mine operators to increase their survival time by having more storage capacity on-site. This ensures that if any disruptions do arise, or even if some tanks are offline for maintenance, they can call on their additional storage and mitigate a stock-out event impacting production.”

Operators are less likely to incur downtime from a hub-and-spoke model as compared with a direct-to-tank system. They are also likely to enjoy greater operational efficiencies.

“A lot of those insights are available from having real-time refuelling information, which is made available by our platform. Are you travelling too far between refuelling points, for example, or can we move infrastructure to more efficient locations?” Arthur said.

“We also look at additional infrastructure data points around refuelling performance and flow rates. Sensors installed right across a miner’s fuel supply chain provide valuable data to understand and optimise their operational processes, with insights analysed through the most reliable platform available.”

While the hub-and-spoke model is best suited to operators using more than 300 million litres of fuel per year, VERIDAPT’s fuel-management solutions are suitable to miners of all sizes and profiles. The model can also be adapted to smaller operations and still realise significant benefits.

Mid-tier miners, for example, can enjoy significant cost savings from being able to monitor their fuel supply chain and make operational changes where necessary. These insights can also be shared with fuel suppliers to improve upstream processes.

“We endeavour to integrate our systems with existing infrastructure,” Arthur said. “The quicker we can get it installed, the quicker the customer gets a value-adding outcome.

“This information is aggregated in a secure cloud infrastructure platform and then disseminated through reports, so it works as an overarching platform that all users can access both on-site or remotely and through multiple devices such as their phone, tablet or computer.

“We provide configurable third-party access to suppliers, so they have visibility of their responsible vendor-managed inventory portion. The system provides visibility for both internal and external parties to monitor and control their complete supply chain from end to end.”

VERIDAPT has developed a reliable and versatile fuel-management solution to suit mine and rail operators of all sizes, with a software platform that can process big data and deliver actionable insights right across a fuel supply chain.

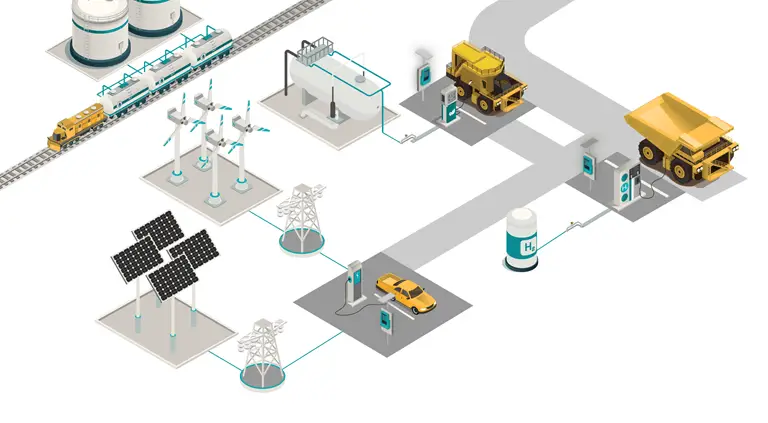

This is pertinent for now and for a decarbonised future, with VERIDAPT set to become an important platform for diverse energy footprints, where mine operators could call on everything from diesel to blended fuels to hydrogen and electrification to power their sites.