Benefits of best fuel management systems in mining

The operational benefits of an appropriate fuel management system for mines fall into four key categories. These are:

|

Labour savings

|

Non-labour cost reduction

|

|

|---|---|---|

|

Automating ■ Record keeping and reporting in one centralised location. ■ Tank gauging to remove manual dipping. Implementing ■ Vendor-managed inventory. Improving ■ Cost allocation and control. |

Controlling and measuring ■ Subcontractor access to fuel and lubricants. Increasing ■ Increasing access to rebates via more accurate reporting. Reducing ■ Theft and misconduct. ■ Stock levels through better inventory management. Eliminating ■ Stockout events at fuel and lubricant facilities, especially for remote locations. Scheduling ■ Maintenance is based on fuel or lubricants burned. Monitoring ■ Lubricant top-ups between maintenance to identify faults early. ■ Facilities performance, such as flow rates or filter condition, to optimise replacement. Providing ■ Traceability of fuel and lubricant products to individual equipment items in case of contamination. ■ Automated confirmation of delivery volumes to ensure accurate deliveries.

|

|

|

Productivity improvements

|

Risk management & improved governance

|

|

|

Reducing ■ The number and frequency of refuelling events. ■ The time of each refuelling event through measurement and benchmarking of operators. Improving ■ Service truck productivity by monitoring throughput and benchmarking. Validating ■ Business improvement projects using data. Using ■ Data to optimise fleet purchase decisions. Identifying ■ Anomalies and outliers to stop waste and prevent significant spending on equipment repairs.

|

|

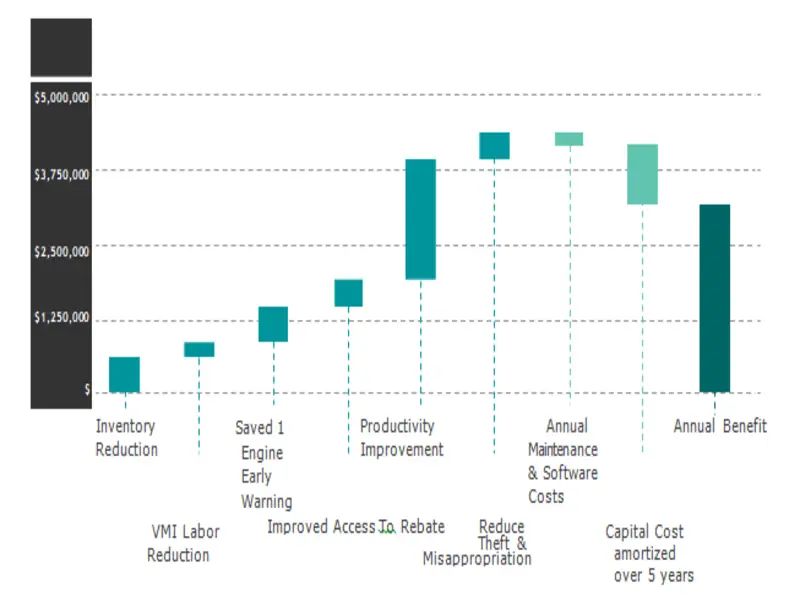

Ratio of benefits

Productivity and safety are key benefits of a best practice. Figure 2, for instance, outlines the ROI and savings obtained by implementing Fuel Management Systems' best practices using Veridapt. Mine site productivity improvements can significantly outweigh costs, often providing 3X to 5X ROI. Improving mine site productivity generally reduces the number of heavy vehicles operating on a site, providing a disproportionately large benefit. Please note that the productivity results shown in Figure 2 have been taken from an actual Australian mine site that spends $110m annually on fuel and lubricants.

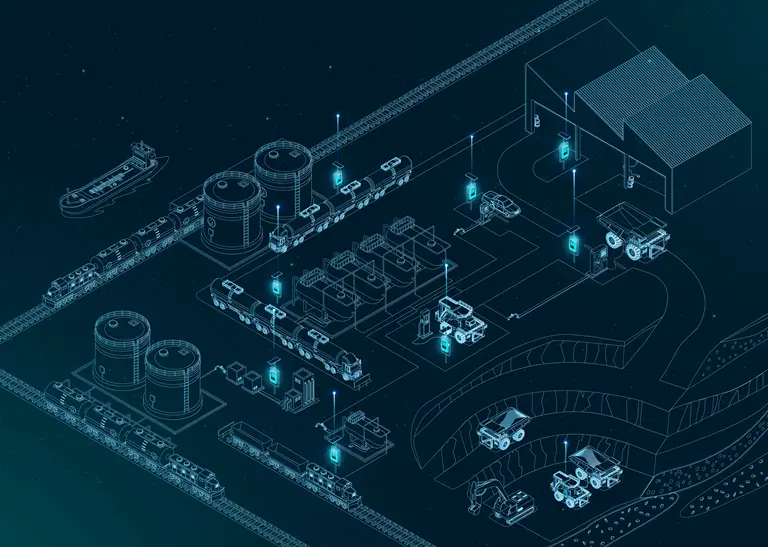

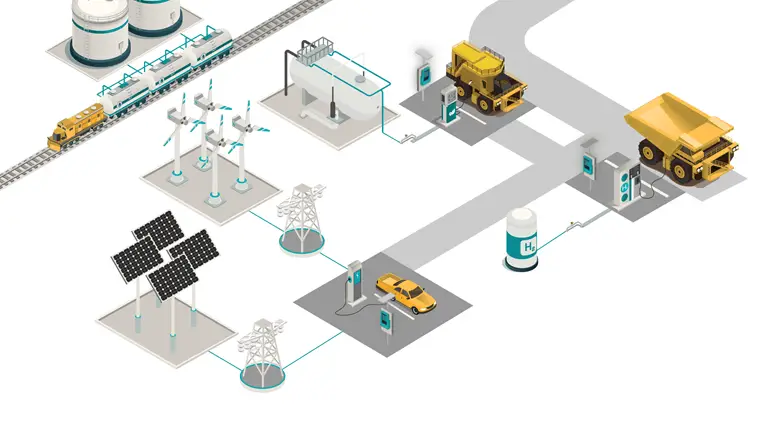

VERIDAPT: supporting fuel management excellence across global industries

Veridapt fuel management systems are engineered to deliver productivity, labor savings, and environmental compliance benefits at scale, whether your mining operations are in Canada, the USA, Africa, Australia, or South America.

Through Veridapt’s automated monitoring, vendor-managed inventory, and advanced analytics, mining operations gain:

-

Improved traceability of fuel and lubricant use by individual equipment assets.

-

Automated fuel and lubricant delivery confirmations to eliminate manual checking.

-

Real-time data to support carbon tax documentation and government EHS compliance.

-

Fuel theft prevention and inventory visibility — even in remote mine sites.

-

Eligibility for fuel rebates requires accurate reporting.

As demonstrated in Australia, North America, and other global markets, Veridapt systems ensure full data capture, compliance, and operational transparency when fuel rebate tracking and environmental reporting are critical.

Implementing a best-practice fuel management system like Veridapt is no longer optional for mines, railroads, or other operations that handle large fuel volumes—it’s essential!

Please read our article on digital fuel management at mine sites to learn how Veridapt is transforming mining fuel systems globally.

This article is an excerpt from Veridapt’s Fueling Best Practice Guide for Mines. For more information, download the complete guide here.