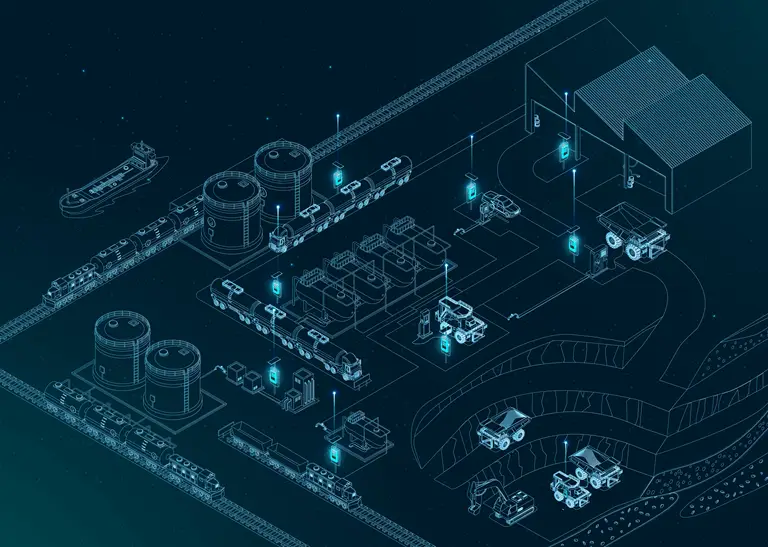

Efficiency and cost control are paramount in the demanding industries of mining and railroads. One critical area for optimization is fuel management. Fuel Management Systems (FMS) provide a comprehensive solution for monitoring, controlling, and managing fuel consumption, leading to significant cost savings and operational improvements.

Understanding the core functionality of industrial fuel management systems

An industrial FMS system typically includes hardware and software components designed to work together seamlessly. Key functionalities include:

-

Real-time Fuel Tracking: Monitoring the precise fuel consumed by vehicles and equipment for accurate accounting and performance analysis.

-

Comprehensive Inventory Management: Tracking fuel levels in storage tanks precisely and managing overall fuel inventory to prevent shortages and optimize purchasing decisions.

-

Secure Access Control: Restricting fuel access to only authorized vehicles and personnel through various authentication methods, minimizing the risk of theft and misuse.

-

Detailed Data Reporting and Analytics: Generating comprehensive reports on fuel usage patterns, costs, and other critical metrics to provide actionable insights for operational improvements.

-

Precise Fuel Dispensing Control: Managing and controlling fuel pumps ensures accurate dispensing quantities and prevents overfilling or wastage.

-

Holistic Fluid Management: Extending beyond fuel to manage essential fluids, including diesel exhaust fluid (DEF), chemicals, oils, and coolants, ensuring proper usage and inventory.

-

Seamless Integration with Enterprise Systems: Integrating existing fleet management systems, accounting software, and other enterprise resource planning (ERP) systems for a unified operational view.

-

Proactive Emissions Monitoring and Reporting: Tracking fuel usage and associated emissions data for environmental regulatory compliance and sustainability reporting initiatives.

-

Continuous Real-time Reconciliation: Ensuring all fuel inflows and outflows across diverse operational sites reconcile in real-time, minimizing discrepancies and identifying potential issues promptly.

-

Granular Automated Transaction Logging: Recording every instance of product movement as a distinct transaction with precise timestamps and detailed information about the involved vehicle, personnel, or asset.

-

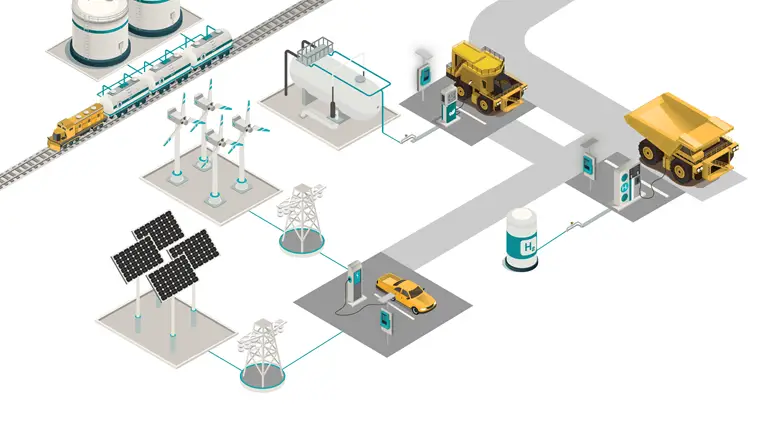

Future Proof: Able to track and manage alternative fuels, including electric vehicle charging, hydrogen, and biofuels.

-

Portable FMS devices: Enabling real-time reconciliation in even the most remote and unsupervised areas by allowing users to easily capture, verify, and reconcile all dispense transactions from service trucks, tanks, or other dispensing equipment without the need to install hardware.

Key benefits of implementing advanced fuel management systems in mining and railroad operations

- Implementing a sophisticated FMS offers numerous tangible benefits for the complex operations of mining and railroad companies:

- Significant Cost Savings through Optimized Fuel Consumption: Reducing fuel consumption by identifying inefficiencies, optimizing routes, and promoting better driving habits.

- Drastic Reduction in Fuel Theft and Fraud: Implementing robust access controls and real-time monitoring to minimize unauthorized fuel withdrawals and fraudulent activities.

- Substantial Improvements in Operational Efficiency: Streamlining the entire refueling process, minimizing equipment downtime, and optimizing resource allocation for enhanced productivity.

- Data-Driven Insights for Informed Strategic Decision-Making: Providing accurate, real-time data enables better forecasting, budgeting, and strategic planning across all operational levels.

- Ensuring Environmental Compliance and Promoting Sustainability: Accurately tracking fuel usage and emissions to meet regulatory requirements and support environmental sustainability goals.

- Enhanced Safety and Reduced Environmental Risk: Preventing fuel spills, ensuring adherence to safe refueling practices, and minimizing the environmental impact of fuel handling.

- Measurable Increases in Equipment and Manpower Productivity: Optimize equipment utilization by ensuring timely refueling and minimizing delays while improving the efficiency of maintenance and operational personnel.

- Lowering Overall Operational Costs through Waste Reduction: Minimizing unnecessary fuel consumption, reducing maintenance costs associated with fuel-related issues, and optimizing inventory management.

- Empowering Better Planning and Resource Allocation: Providing accurate data on fuel consumption patterns to facilitate more effective planning of routes, schedules, and resource deployment.

- Contributing to Enhanced Sustainability and a Reduced Carbon Footprint: Optimizing fuel usage and identifying opportunities for transitioning to more sustainable energy sources. Learn more about how fuel management systems can impact your operations – Contact us today to explore solutions customized to your industry.

Leading fuel management system providers for mining and railroad industries

Here's a detailed look at some of the leading companies in the FMS market and their offerings, with a specific focus on solutions tailored for the complex needs of mining and railroad operations:

VERIDAPT: industrial-focused FMS for unmatched reliability and actionable insights

VERIDAPT stands out as a leader in industrial fuel management technology, committed to delivering unparalleled transparency, reliability, and efficiency throughout the fuel supply chain. Their exclusive focus on FMS for industrial markets, particularly mining and railroads, allows them to engineer solutions that precisely address the unique challenges of these sectors. VERIDAPT's AdaptFMS platform currently monitors, controls, and authorizes over 30 billion liters of fuel annually across more than 200 large-scale global mining, rail, and industrial operations.

-

Core Functionality of AdaptFMS: VERIDAPT's comprehensive AdaptFMS platform meticulously tracks the entire lifecycle of fuel and lubricants, from initial delivery to final consumption. Key features include robust real-time reconciliation capabilities, significant enhancements in operational productivity, optimized asset efficiency, substantial cost optimization, stringent security protocols, and precise emissions monitoring. The system intelligently aggregates data from diverse field devices, such as highly accurate tank level gauges and flow meters, presenting this information in easily understandable formats suitable for mandatory statutory reporting and in-depth internal analysis. AdaptFMS provides unprecedented visibility into fuel and lubricant usage, down to the individual consuming asset, enabling granular control and analysis. AdaptFMS is also futureproof, enabling tracking of EV electric vehicle fuel charging and other emerging fuels. Read over 10 case studies highlighting the real-world impact of Veridapt Fuel Management Systems.

-

Key Benefits for Mining and Railroad Engineers: VERIDAPT's core value proposition lies in delivering actionable intelligence that directly translates into tangible fuel savings, significantly reduced fuel theft incidents, and improved overall operational efficiency. Their advanced data analytics capabilities help identify subtle performance issues with specific assets, enabling proactive maintenance interventions and continuous operational optimization.

-

Tangible Results from VERIDAPT Case Studies: VERIDAPT's platform consistently delivers significant value to its clients through its real-time commodity tracking technology and sophisticated workflow automation. The platform has a proven track record of effectively mitigating the risks associated with theft and fraud at every stage of the fuel supply chain by providing end-to-end inventory and transactional transparency. Furthermore, VERIDAPT's technology is specifically engineered to maximize operational efficiencies by providing the data needed to optimize refueling schedules and identify waste areas. For instance, one South American mining company used VERIDAPT’s Adapt SMU Tags to identify abnormal fuel burn rates across their fleet, resulting in annual fuel savings of over 1.7 million litres, or approximately $2.55 million USD. Read the full case study here.

-

VERIDAPT's Pedigree and Commitment to Quality: With more than twenty years of dedicated experience in the industrial FMS sector, VERIDAPT is a 100% Australian-owned company with a strong and established presence in the demanding Australian mining environment. Their commitment to quality is underscored by their ISO9001 certification for quality management systems and SOC2*Type 2 certification for stringent security protocols. VERIDAPT's hardware is proudly manufactured in Sydney and designed to sustain high availability and reliable performance in the most challenging operational conditions. They maintain a dedicated in-house team of software and hardware engineers, allowing for rapid customization and responsive support tailored to the unique needs of their clients.

Banlaw: global leader in fluid asset intelligence with a strong industry heritage

Banlaw provides fluid asset intelligence solutions, offering FMS technologies for various industries.

- Banlaw's FMS Functionality: engineered to track diesel and other fluids, optimize the refueling process for efficiency, and implement security measures for fluid asset management. The ResTrack RMS software provides a centralized platform for automating security protocols, access control management, monitoring fluid levels and usage, and reconciling hydrocarbon and other liquid assets. Banlaw's FMS is designed to provide integration across all aspects of fluid management.

- Benefits for Large-Scale Operations: Banlaw's clients report cost savings and improvements in operational efficiency. Their hardware is claimed to be specifically engineered to withstand the rigors of harsh industrial environments.

Smartfill (FMT): robust and user-friendly FMS designed for harsh environments

Smartfill, offered by FMT, provides FMS solutions specifically engineered to perform reliably in demanding industrial environments.

- Smartfill's Integrated Data Management: SmartFill integrates critical data points, including fuel and oil usage, vehicle data, and real-time inventory levels, into a unified solution. The system offers automated reporting capabilities, flexible authentication to ensure secure access, and fuel reconciliation features for accurate tracking. The latest GEN 3 platform leverages cloud-based technology to efficiently manage data for up to 50,000 vehicles and drivers.

- Key Advantages for Operational Efficiency and Security: SmartFill prioritizes fuel security, maximizing fuel efficiency, and accountability. By automating data collection and reporting, Smartfill makes information accessible online, empowering informed decision-making and proactive management.

Orpak: comprehensive fleet solutions leveraging global expertise

Orpak, a part of Gilbarco Veeder-Root, delivers scalable solutions for oil companies and commercial fleets, including tailored offerings for industrial applications in mining and railroads.

- Orpak's End-to-End Fleet Management Capabilities: Orpak's Fleet Solutions provide end-to-end automation and management for home-based and remote commercial and industrial operations. Key features include fueling control and authorization based on vehicle and driver identification, automated fuel loss monitoring systems, and customizable reporting capabilities to meet specific operational needs. Orpak's ForeFuel system enables fast refueling through automatic vehicle identification (AVI) technology.

- Benefits Focused on Margin Improvement and Visibility: Orpak's solutions help organizations increase operating margins by optimizing fuel consumption and providing visibility and control over fuel inventory. Their solutions cater to a wide range of operational requirements.

Providing mining and railroad operations engineers with robust and reliable solutions

Industrial engineers require FMS solutions that offer robust performance and reliability in demanding environments and seamlessly integrate with their existing infrastructure. Fuel management systems are critical components for optimizing productivity, providing the actionable information necessary for optimizing fuel consumption and achieving significant operational efficiencies.

Conclusion: investing in intelligent fuel management for a sustainable and efficient future

Fuel Management Systems are no longer a luxury but an absolute necessity for optimizing operations within the harsh environments of the mining and railroad industries. By providing comprehensive control, granular visibility, and actionable insights into fuel consumption, these intelligent systems enable organizations to achieve significant cost reductions, enhance operational efficiency, improve security protocols, and ensure environmental compliance. Leading FMS companies, such as VERIDAPT, Banlaw, Smartfill, and Orpak, offer diverse solutions with varying functionality and durability.

VERIDAPT's unwavering focus on the industrial sector, coupled with its mil-spec hardware designed for maximum uptime, straightforward one-day installation, and robust data analytics capabilities, positions it as a compelling choice for mining and railroad companies seeking tangible fuel savings, a reduction in theft, and significant improvements in overall operational efficiency.

Are you interested in learning how a VERIDAPT fuel management solution can boost your productivity and reduce fuel theft? Contact our regional office or get in touch today to speak with specialists.

The information above has been compiled from publicly available sources and is believed to be accurate as of the time of publication. Company and product names are the property or trademarks of the individual companies.