Mining technology companies don’t usually take cues from Hollywood, but VERIDAPT, a leader in fuel management solutions, has launched a new short film designed to grab the attention of the mining community.

Partly shot in the same quarry used for the most recent Mad Max film and voiced by the unmistakable voice of MythBusters’ Robert Lee, VERIDAPT’s upcoming campaign puts its hardware through the ultimate test.

The film shows units enduring dust storms, relentless heat, muddy water plunges, and earth-shaking vibration. Some units were even frozen in ice.

It’s a cinematic way of driving home a very serious message: when you operate in extreme mining environments, your technology needs to be as tough as the terrain.

“We wanted to highlight that we don’t just lab test our products, we prove them in the field under the same conditions our customers face every day and beyond,” VERIDAPT co-founder and chief technology officer Sean Birrell told Australian Mining. “The campaign is playful, but it’s also rooted in real-world experience.”

The videos, produced in multiple formats ranging from 30-second snippets to a full four-minute feature, were released across digital platforms in September.

With high production values and an advertising director from the Mad Max film crew, VERIDAPT is signalling that this isn’t just another product demo — it’s a statement of intent.

The campaign reflects VERIDAPT's core design philosophy, which sees the company build its mining hardware from the ground up.

“Mining was our first market,” Birrell said. “We knew from the outset the environment was unforgiving, so our hardware had to be built fit for purpose, not retrofitted after the fact.”

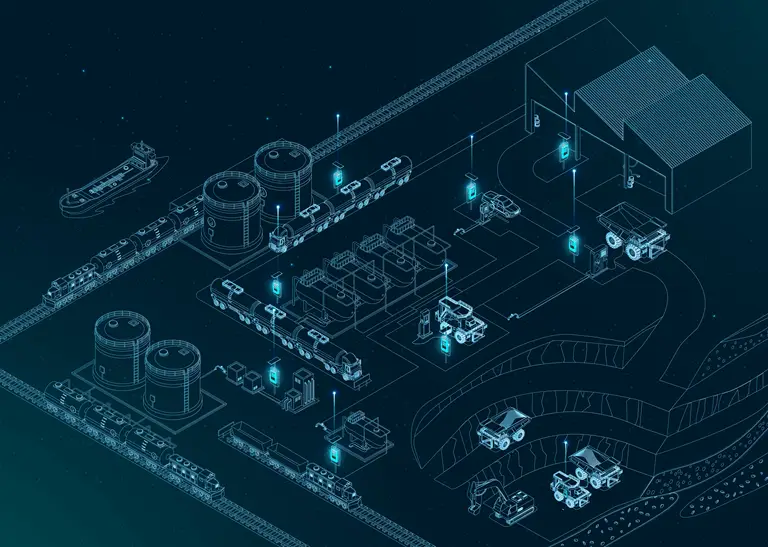

This approach has paid dividends. VERIDAPT’s fuel management systems are proven on service trucks, fixed plant, and rail applications where vibration, dust, remoteness and heat constantly threaten less robust equipment.

Industry certifications like IP ratings, temperature and vibration standards only go so far. VERIDAPT takes testing a step further, combining lab-based quality assurance with years of field experience to replicate the extreme scenarios miners face every day.

The company’s engineers have recovered units after incidents such as vehicle fires and rollovers.

One example involved pulling data from a unit salvaged from a burnt-out vehicle, a testament to the system’s resilience.

“Real-world experience is unsurpassed,” Birrell said. “That’s why we design our products with headroom, so they keep operating even in exceptional circumstances.”

VERIDAPT hardware is known for its durability and ability to thrive in the harshest mining conditions

Durability alone isn’t enough, and VERIDAPT has married toughness with intelligent design, ensuring its hardware and cloud software work seamlessly together.

Unlike many providers, VERIDAPT owns its entire technology stack — from printed circuit boards to cloud applications — enabling deep integration across different site infrastructures, ERP (enterprise resource planning) systems, and supplier networks.

“Fuel supply chains in the mining industry are complex,” Birrell said. “Some use vendor-managed inventory, others have very different logistics. “Our system adapts to those workflows while maintaining reliability.”

The system’s wide sensor compatibility, asynchronous offline operation, and modular plug-and-play hardware allow sites to maintain continuity even during outages, while repairs can be completed in minutes without disrupting data integrity.

From the Arctic Circle to the deserts of Australia, VERIDAPT’s systems have been deployed in some of the most extreme environments on Earth.

The company’s reputation for reliability has grown among operators who prioritise uptime and dependability. Ease of use has also been central to VERIDAPT’s growth.

Simple touchscreen technology is improving operator experience in the field, while flexible software reporting supports diverse operational workflows.

“Reliability has been a hallmark of our hardware,” Birrell said. “But we’ve also worked hard on usability, because it’s the people in the field who rely on these systems every day.”

This year, VERIDAPT launched its latest hardware platform. Building on the ruggedness of previous generations, AdaptNX introduces even greater modularity, scalability, and serviceability.

Cabling has been minimised to reduce points of failure, while components are designed for quick swap-outs without disrupting permanent connections.

“Every new product incorporates lessons from the field,” Birrell said. “AdaptNX continues that tradition, improving reliability but also making systems easier to service and scale.”

As mining operations face mounting cost pressures, many are becoming increasingly remote, meaning rugged and intelligent technology is no longer optional — it’s essential.

VERIDAPT’s latest campaign, with its cinematic flair and MythBusters voice-over, is more than an eye-catching advertisement. It’s a reminder that in mining, hardware must do more than meet lab standards — it must survive reality.

“Our philosophy has always been about fit-for-purpose design and continual improvement,” Birrell said. “This is what makes the difference when your equipment is operating at the edge of what’s possible.”