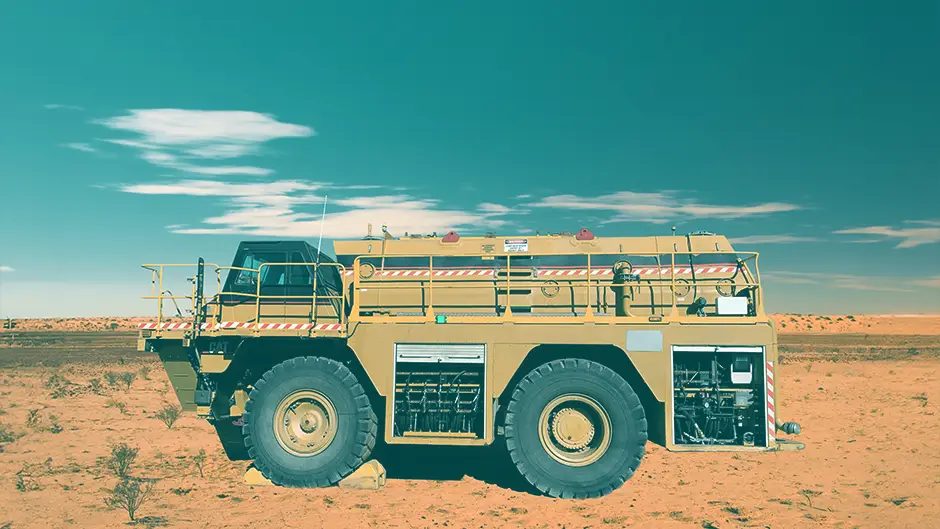

Service truck productivity

Miner eliminates US$850K + in annual fuel and labor costs by improving service truck productivity

Problem

A new mining client came to VERIDAPT after detecting frequent large disparities between service truck productivity both within a site and between sites, resulting in costly underperformance across its operations and unsatisfactory KPIs.

One site discovered a 40% productivity variance between sites when measured by the number of transactions and volume of fuel dispensed per shift. On the poorest performing site this necessitated the operation of an additional service truck when compared to the best performing sites for an equivalent workload. This represented an additional cost of $1.1M annually plus capital and operating cost.

Solution

Rugged and reliable VERIDAPT fuel management hardware was deployed to the sites and paired with VERIDAPT enterprise ready AdaptIQ software to monitor and digitally record every step and action related to the fuel supply chain in real time.

It was evident that capturing and collating accurate data on fleet size and makeup, operator behaviour, refuelling strategy and site topography was a critical step in controlling the variability in service truck productivity.

This led to moving the average dispense volume per shift from 15,000L to 22,500L.

Benefit

By increasing the average dispense volume per shift the client was able to operate one less service cart, resulting in annual savings of US$850K based on the following calculation: Service truck operating cost equals $250K annually Plus Operator Costs (4 operators in total) equals $600K annually. The calculation did not include asset related savings such as depreciation savings or financing costs.