Pitstop performance

We added US$1.7M in operating profit by optimising refuelling performance at a large coal mine

Problem

A coal mining client was experiencing large discrepancies between the refuelling performance and frequency of various haul truck crews. These costly discrepancies were impossible to detect until long after the fact, creating an immediate need for full real-time transparency of the entire fuel supply chain.

Solution

VERIDAPT’s team of fuel management champions trained in data-driven analytics, examined every stage of the refuelling process for each equipment item, facilitating fleet optimisation at the refuelling point. This minimised fleet refuelling congestion, ensuring the shortest refuelling time for mining trucks, hence a much higher truck fleet utilisation.

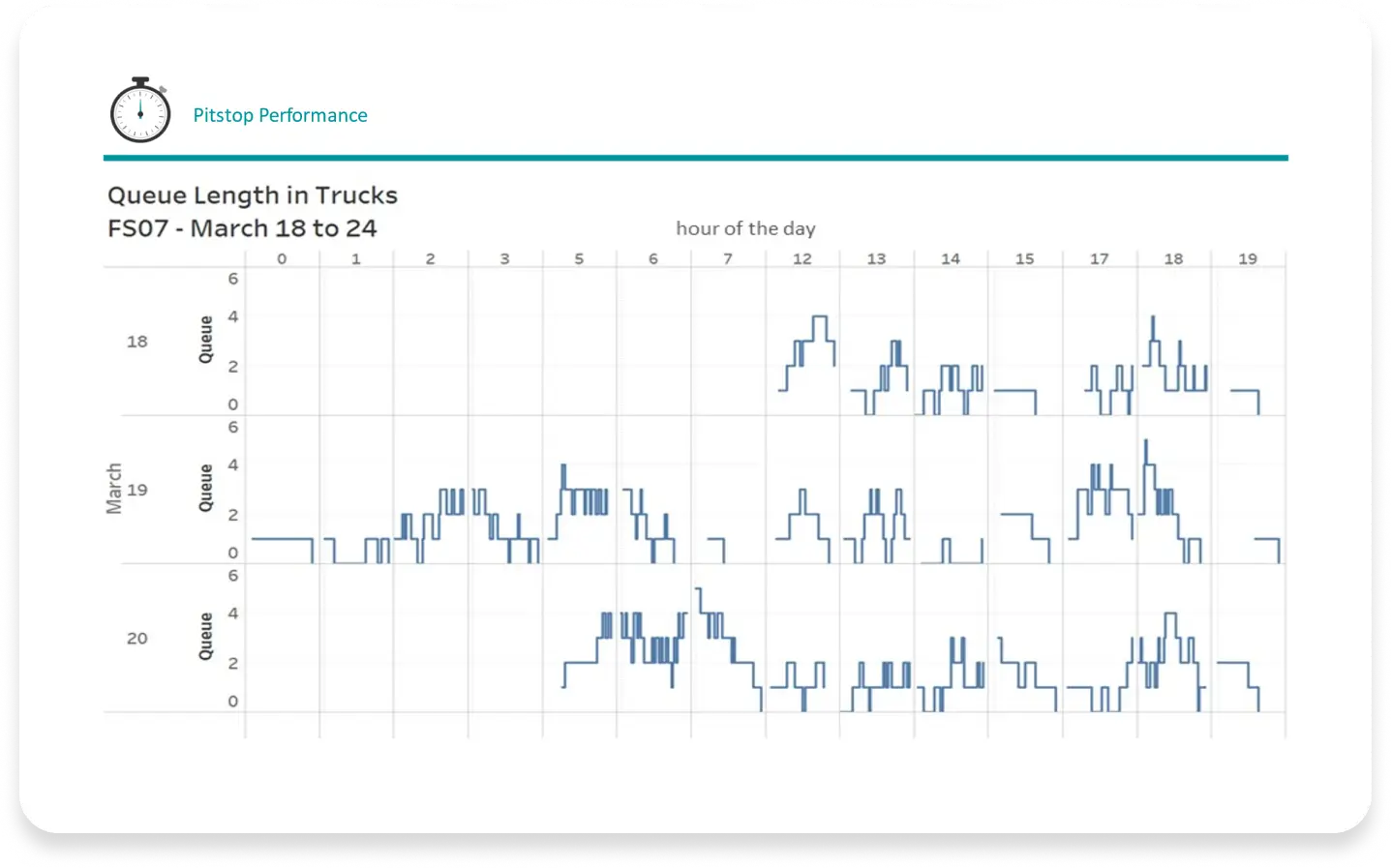

Average waiting times at the studied refueling points was 3.3 minutes, ranging from 20.3 minutes to 0 minutes, over 3 different pits over one day. The queue diagrams demonstrated that there were several opportunities to reduce the truck queue by: better distribution of assignments to refuelling across the shift; increase fuel locations utilisation by assigning trucks during idle hours; increase capacity (ie. flow rate) at highly utilised locations.

Benefit

By providing fleet dispatchers with real-time visibility to decide the best time to assign a truck for refuelling, the client was able to reduce fleet down time and accurately track and reconcile the entire fuel supply chain from procurement through consumption, labour and operating costs.

The result was a reduction in the average waiting time by 1-minute unlocking 990 truck-hours per year, equivalent to $1.7M USD in additional production profit for the mine.