The high cost of diesel makes it imperative that every litre burned at the mine site is accounted for and documented to maximise the Australian Diesel Fuel Tax Rebate.

Diesel rebates exist to compensate industries like mining that do not use public roads and consume high volumes of diesel in remote locations.

The U.S. Energy Information Administration (EIA) recently raised its U.S. diesel price forecasts for 2023 and 2024, meaning Australian miners should also be bracing for higher fuel input costs. Adding to the pain is the strong U.S. dollar.

“Analysis of detailed dispensing data provides the opportunity to realise the maximum rebate, whilst managing the risks of compliance. However, where a lack of data exists, a more cautious approach is required often leading to a reduced claim,”

said Jason Edwards, Hydrocarbons Systems Consultant.

Fortunately for the mining sector, Australia has no current plans to abolish the Diesel Fuel Tax Rebate, resisting some political pressures to do so.

So why do many mining companies short-change themselves at tax time by under-reporting diesel fuel consumption?

Here are some of the most common shortfalls that can lead to lower rebates, according to VERIDAPT, a leader in fuel management for many of the world’s biggest mining companies:

- Fuel delivery monitoring and reconciliation manually, outside of the fuel management systems (FMS)

- Service trucks left unmonitored

- Incomplete data on the consuming vehicle

- Non-automated fuel authorisation

- Unreliable FMS

“AdaptFMS has proven it can address all these shortfalls and maximise the diesel tax rebate through greater transparency and traceability”

said Wayne Arthur, VERIDAPT’s VP of Mining.

Arthur stresses that at the current rebate rate set by the Australian Tax Office of 48.8c/litre there is no reason to leave money on the table.

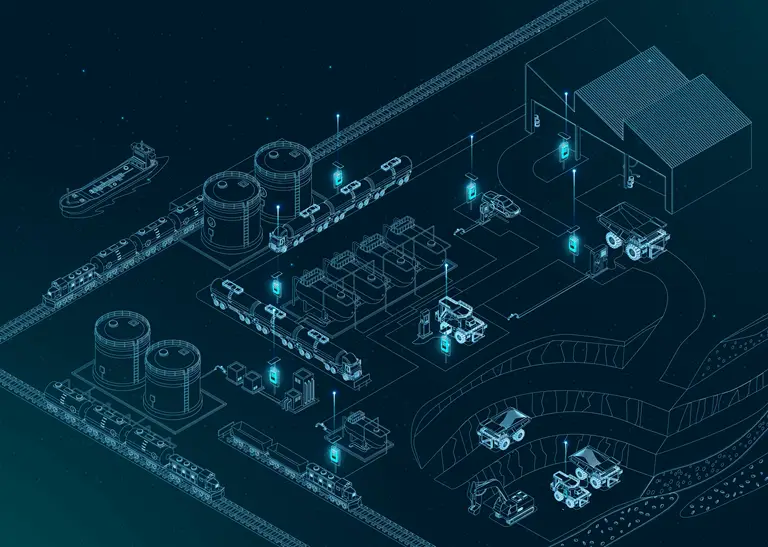

VERIDAPT’s digital platform monitors, controls and authorises the use of over 30 billion litres of fuel annually, across 80+ large global mining, rail and terminal operations. Clients include BHP, Rio Tinto, Glencore, Vale, Teck, Syncrude and major rail companies.

Maximising a rebate can be complex.

It is important for any fuel management system to have the capability to accurately differentiate between light and heavy vehicle usage as rebate rates will vary accordingly, based on ATO guidelines.

A recent VERIDAPT client experience at a major Australian coal mine accurately illustrates the overwhelming benefits of a digitally-based fuel management solution.

Firstly, on-site fuel use was identified by itemising fuel consumption to each individual fuel-consuming asset, as some light vehicles were only ever used for on-site purposes. In this way, the system provided a verified data trail from initial purchase to consumption, ‘buy to burn’.

Importantly, the client also wanted to keep records of the fuel they were using while offsite (e.g., travelling on public roads), which isn’t eligible for rebates. The Australian Tax Office stipulates that if fuel rebates are to be claimed, a wide range of information needs to be stored for up to five years.

The client now has accurate ATO-auditable records mitigating compliance risk for their fuel purchase, use and consumption.

“This is a significant improvement on the previous system, where the client simply claimed rebates based on their fuel purchase invoices, leaving them open to under or over-claiming,” Arthur said.

“Without an automated FMS, it typically takes 2 to 3 weeks out of each month to gather all the data required, then calculate and lodge to the ATO. With an automated FMS, these functions can be performed mostly in real time, adding extra levels of reliability and efficiency,” added Edwards.

For the latest on tax rebate, click here.

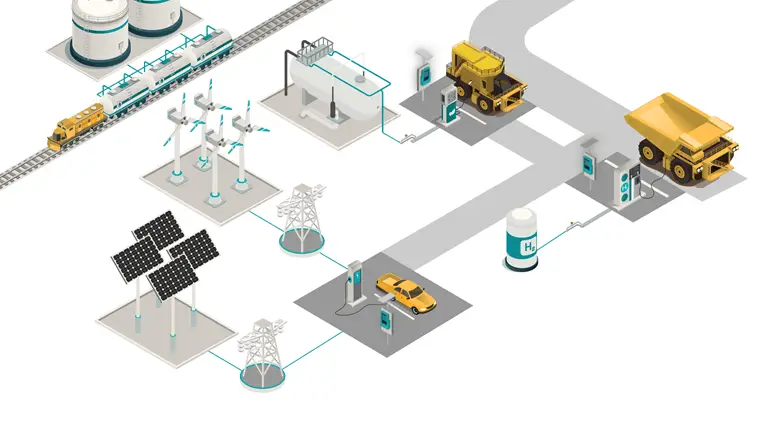

The mining sector continues to make great strides into renewable energy sources, but experts agree the transition will take time and that diesel and other liquid fuels will continue to play an integral role for some time to come.

“Tracking energy usage in the energy transition at the mine site promises to be a growth opportunity tailor-made for the digital innovators in hydrocarbon management,”

according to VERIDAPT’s, Arthur.

“Effective digital fuel management into the future must address an increasing number of energy options,” Arthur said.

In recognition of the energy transition underway, the ATO also spells out rebate structures for biofuels and blended fuels.

VERIDAPT has also teamed with BHP in trialing the use of Hydrotreated Vegetable Oil (HVO) to help power mining equipment at one of its iron ore mines in Australia. Supplied through a collaboration between BHP and BP, the renewable diesel made from HVO is earmarked for use in haul trucks and other mining equipment.

“As new fuels increasingly enter the mainstream, we will be challenged with tracking multiple products and rebate profiles throughout the supply chain,”

Edwards added. “This is adding to the importance of an efficient digital fuel management platform.”

According to Ernst & Young’s 2024 ranking of the top business risks and opportunities in mining and metals, miners are data rich, but many struggle to manage and capture insights from this wealth of information.

And many lack an integrated approach to technology implementation, limiting the value it can bring to the business, EY adds.

“The digital technology to vastly improve fuel management at the mine site clearly exists. It is up to companies, such as VERIDAPT and the miners themselves, to ensure this technology is exploited to its full potential,” said Arthur.